Novastar A8s-N Receiving Card LED Display Card For Nova AxS Series Receiver Full Color LED Display

Introduction

Supporting the exclusive Image Booster technology of NovaStar, the A8s-N can precisely calibrate the color gamut and grayscale of the screen, and improve the grayscale by 64 times. It also supports the pixel level brightness and chroma calibration, quick seam correction, low latency, 3D, individual gamma adjustment for RGB, image rotation in 90°increments, free image rotation, HDR, and other functions, significantly improving the brightness, grayscale and color performance from every aspect and offering users an ultimate visual experience with a uniform, smooth and life like image.

The A8s-N uses high-density connectors for communication to limit the effects of dust and vibration, resulting in high stability. It supports up to 32 groups of parallel RGB data or 64 groups of serial data (expandable to 128 groups of serial data). Its reserved pins allow for custom functions of users. Thanks to its EMC Class B compliant hardware design, the A8s-N has improved electromagnetic compatibility and is suitable for various on-site setups that have high requirements.

Features

Improvements to Display Effect

⬤ Image Booster (Effects depend on the driver IC)

- Color Management: Support the standard color gamuts (Rec.709, DCI-P3 and Rec.2020) and custom color gamuts, enabling more precise colors on the screen.

- Precise Grayscale: Individually correct the 65,536 levels of grayscale (16bit) of the driver IC to fix the display problems at low grayscale conditions, such as brightness spikes, brightness dips, color cast and mottling. This function can also better assist other display technologies, such as 22bit+ and individual gamma adjustment for RGB, allowing for a smoother and uniform image.

- 22bit+: Improve the LED display grayscale by 64 times to avoid grayscale loss due to low brightness and allow for more details in dark areas and a smoother image.

⬤ Pixel level brightness and chroma calibration

Work with NovaStar’s high-precision calibration system to calibrate the brightness and chroma of each pixel, effectively removing brightness differences and chroma differences, and enabling high brightness consistency and chroma consistency.

⬤ Quick adjustment of dark or bright lines

The dark or bright lines caused by splicing of cabinets or modules can be adjusted to improve the visual experience. This function is easy to use and the adjustment takes effect immediately.

⬤ Low latency

For PWM driver ICs, the latency of video source on the receiving card end can be reduced to 1 frame. For DCLK continuous PWM driver ICs, to use low latency, the customized firmware is required.

⬤ 3D

Working with the LED controller that supports 3D function, the receiving card supports 3D image output.

⬤ Individual gamma adjustment for RGB

Working with NovaLCT (V5.2.0 or later) and the LED controller that supports this function, the receiving card supports individual adjustment of red gamma, green gamma and blue gamma, which can effectively control image non-uniformity at low grayscale conditions and white balance offset, allowing for a more realistic image.

⬤ Image rotation in 90° increments

The display image can be rotated in multiples of 90°(0°/90°/180°/270°).

⬤ Image rotation at any angle

Working with SmartLCT and the MCTRL R5 LED controller, the receiving card supports image rotation at any angle.

⬤ HDR

- Support HDR10 and comply with the SMPTE ST 2084 and SMPTE ST 2086 standards.

- Support HLG.

Improvements to Maintainability

⬤ Smart module (dedicated firmware required)

Working with the smart module, the receiving card supports module ID management, storage of calibration coefficients and module parameters, monitoring of module temperature, voltage and flat cable communication status, LED error detection, and recording of the module run time.

⬤ Automatic module calibration

After a new module with flash memory is installed to replace the old one, the calibration coefficients stored in the flash memory can be automatically uploaded to the receiving card when it is powered on, ensuring high consistency for both display brightness and chroma.

⬤ Quick uploading of calibration coefficients

The calibration coefficients can be quickly uploaded to the receiving card, improving efficiency greatly.

⬤ Module Flash management

For modules with flash memory, the information stored in the memory can be managed. The calibration coefficients and module ID can be stored and read back.

⬤ One click to apply calibration coefficients in module Flash

For modules with flash memory, when the Ethernet cable is disconnected, users can hold down the self-test button on the cabinet to upload the calibration coefficients in the flash memory of the module to the receiving card.

⬤ Mapping 1.0

The cabinets display the receiving card number and Ethernet port information, allowing users to easily obtain the locations and connection topology of receiving cards.

⬤ Setting of a pre-stored image in receiving card

The image displayed during startup, or displayed when the Ethernet cable is disconnected or there is no video signal can be customized.

⬤ Temperature and voltage monitoring

The temperature and voltage of the receiving card can be monitored without using peripherals.

⬤ Cabinet LCD

The LCD module connected to the cabinet can display the temperature, voltage, single run time and total run time of the receiving card.

⬤ Bit error detection

The Ethernet port communication quality of the receiving card can be monitored and the number of erroneous packets can be recorded to help troubleshoot network communication problems.

⬤ Status detection of dual power supplies

When two power supplies are used, their working status can be detected by the receiving card.

⬤ Firmware program readback

The firmware program of the receiving card can be read back and saved to the local computer.

⬤ Configuration parameter readback

The configuration parameters of the receiving card can be read back and saved to the local computer.

Improvements to Reliability

⬤ Dual card backup and status monitoring

In an application with requirements for high reliability, two receiving cards can be mounted onto a single hub board for backup. When the primary receiving card fails, the backup card can serve immediately to ensure uninterrupted operation of the display.

The working status of the primary and backup receiving cards can be monitored in NovaLCT V5.2.0 or later.

⬤ Loop backup

The receiving cards and the LED controller form a loop via the primary and backup line connections. When a fault occurs at a location of the lines, the screen can still display the image normally.

⬤ Dual backup of configuration parameters

The receiving card configuration parameters are stored in the application area and factory area of the receiving card at the same time. Users usually use the configuration parameters in the application area. If necessary, users can restore the configuration parameters in the factory area to the application area.

⬤ Dual program backup

Two copies of firmware program are stored in the receiving card at the factory to avoid the problem that the receiving card may get stuck abnormally during program update.

⬤ Dual backup of calibration coefficients

The brightness and chroma calibration coefficients are stored in the application area and factory area of the receiving card at the same time. Users usually use the calibration coefficients in the application area. If necessary, users can restore the calibration coefficients in the factory area to the application area.

Appearance

All product pictures shown in this document are for illustration purpose only. Actual product may vary.

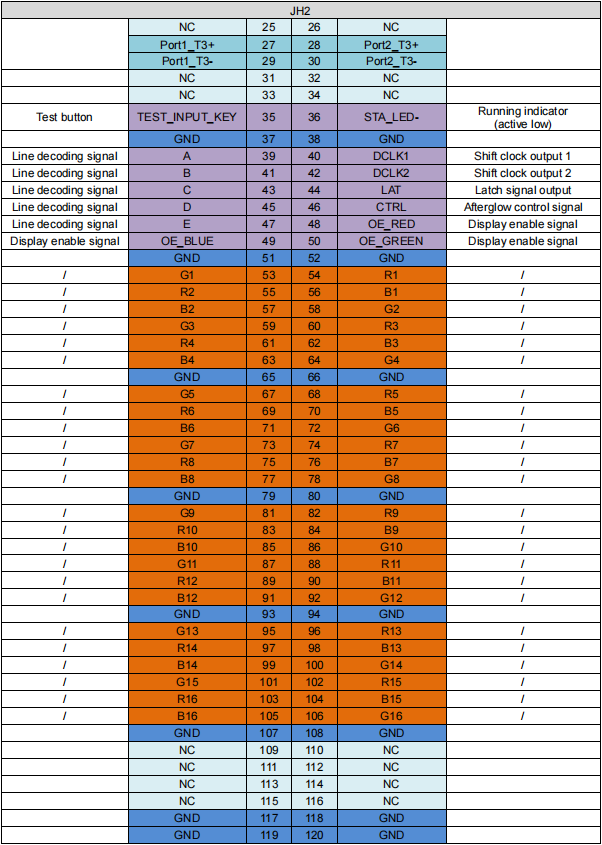

Indicators

| Indicator | Color | Status | Description |

| Runningindicator | Green | Flashing once every 1s | The receiving card is functioning normally. Ethernet cable connection is normal, and video source input is available. |

| Flashing once every 3s | Ethernet cable connection is abnormal. | ||

| Flashing 3 times every 0.5s | Ethernet cable connection is normal, but no video source input is available. | ||

| Flashing once every 0.2s | The receiving card failed to load the program in theapplication area and is now using the backup program. | ||

| Flashing 8 times every 0.5s | A redundancy switchover occurred on the Ethernet port and the loop backup has taken effect. | ||

| Powerindicator | Red | Always on | The power input is normal. |

Dimensions

The board thickness is not greater than 2.0 mm, and the total thickness (board thickness + thickness of components on the top and bottom sides) is not greater than 8.6 mm. Ground connection (GND) is enabled for mounting holes.

Note:

The distance between outer surfaces of the A8s-N and hub boards after their high-density connectors fit together is 5.0 mm. A 5-mm copper pillar is recommended.

To make molds or trepan mounting holes, please contact NovaStar for a higher-precision structural drawing.

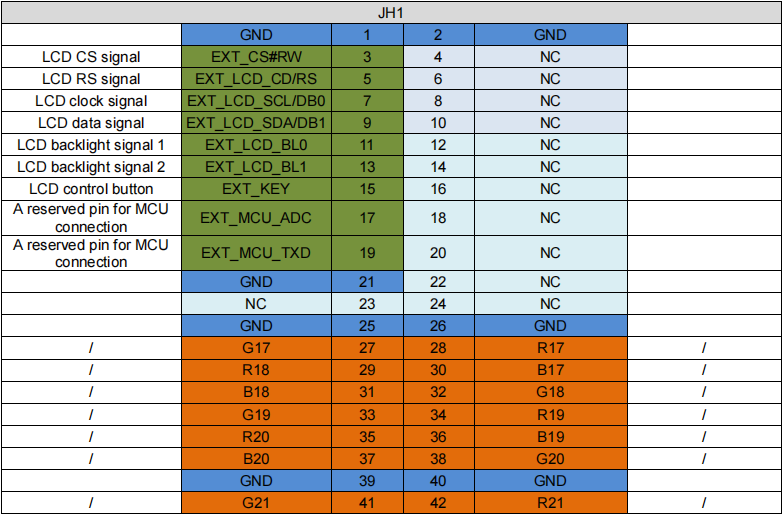

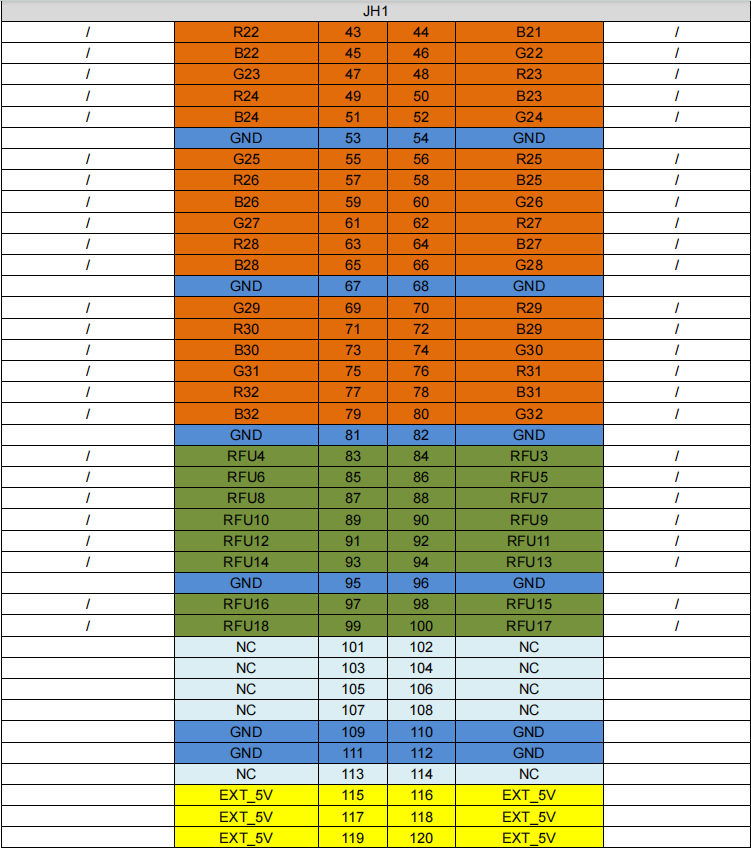

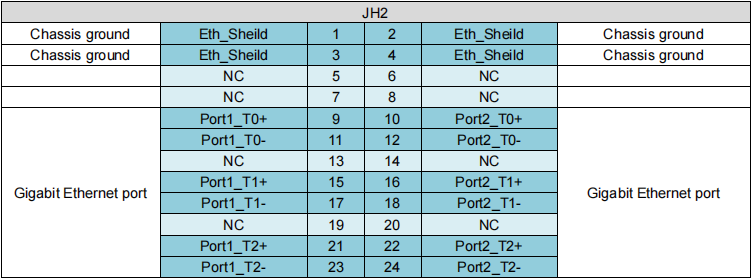

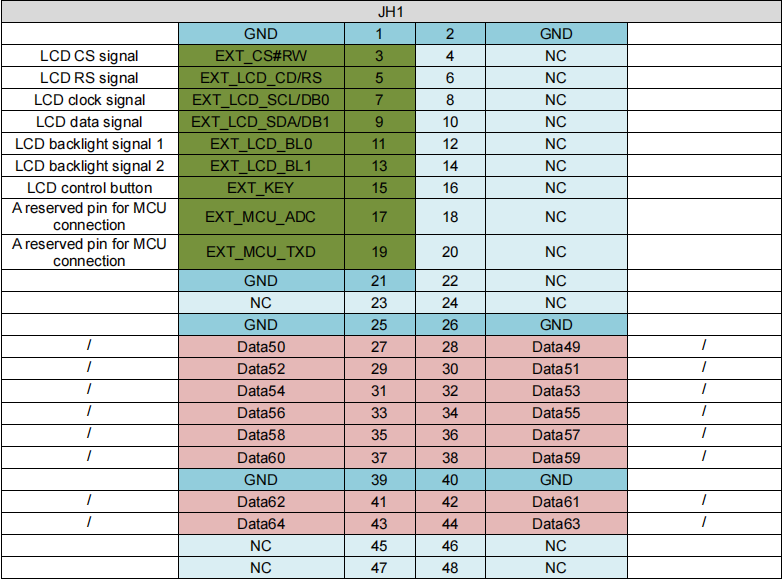

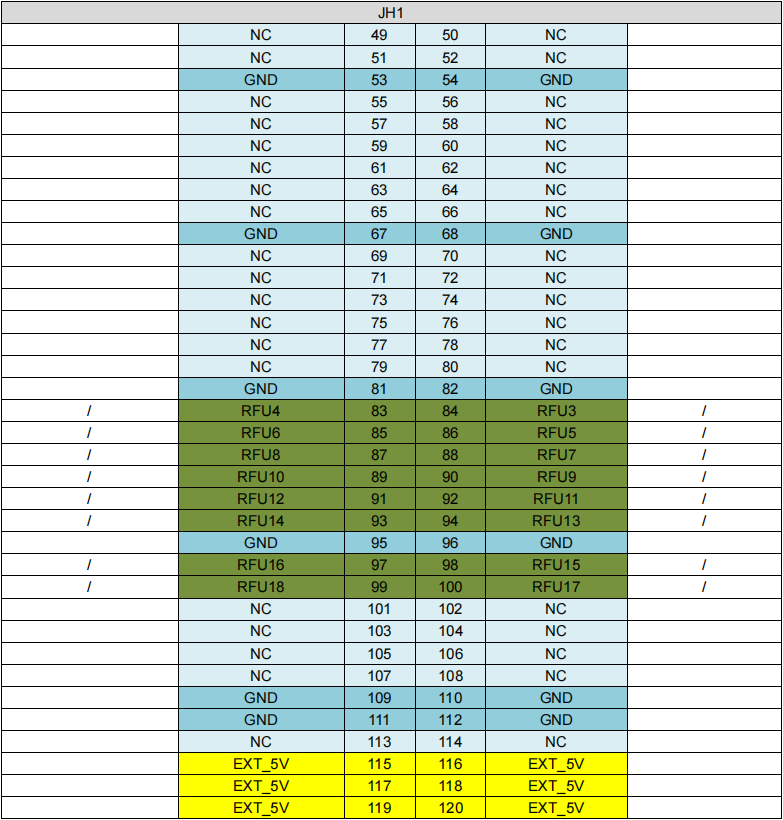

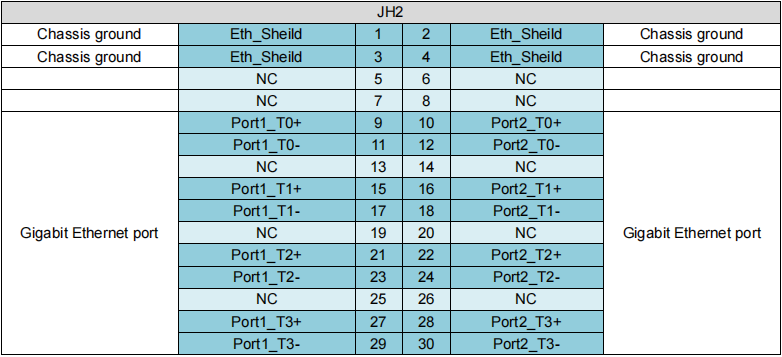

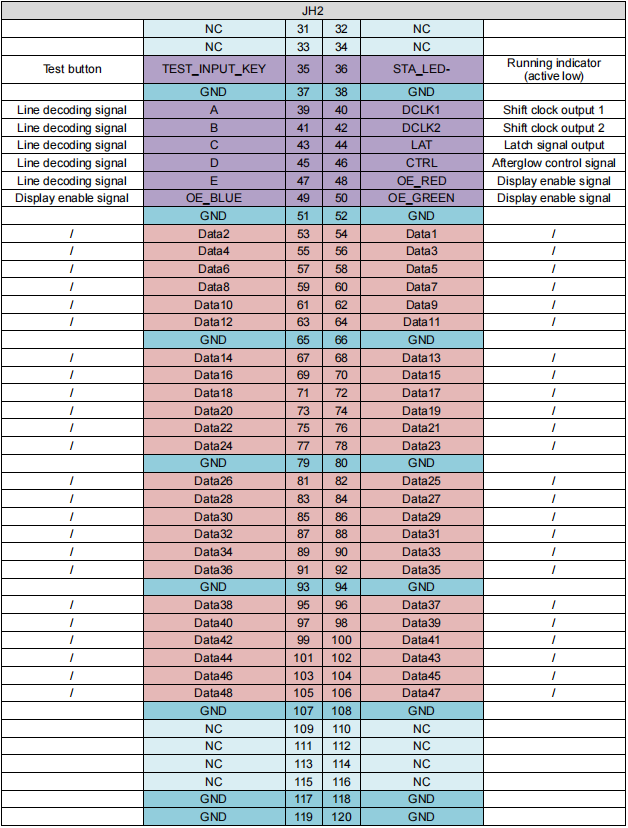

PINS

32 Groups of Parallel RGB Data

64 Groups of Serial Data

Note:

The recommended power input is 5.0 V.

OE_RED, OE_GREEN and OE_BLUE are display enable signals. When RGB are not controlled separately, use OE_RED. When the PWM chip is used, they are used as GCLK signals.

In the mode of 128 groups of serial data, Data65-Data128 are multiplexed into Data1-Data64.

Reference Design for Extended Functions

| Pins for Extended Functions | |||

| Pin | RecommendedSmart Module Pin | RecommendedModule Flash Pin | Description |

| RFU3 | HUB_CODE0 | HUB_CODE0 | Flash control pin 1 |

| RFU4 | HUB_SPI_CLK | HUB_SPI_CLK | Clock signal of serial pin |

| RFU5 | HUB_CODE1 | HUB_CODE1 | Flash control pin 2 |

| RFU6 | HUB_SPI_CS | HUB_SPI_CS | CS signal of serial pin |

| RFU7 | HUB_CODE2 | HUB_CODE2 | Flash control pin 3 |

| RFU8 | / | HUB_SPI_MOSI | Module Flash data storage input |

| HUB_UART_TX | / | Smart module TX signal | |

| RFU9 | HUB_CODE3 | HUB_CODE3 | Flash control pin 4 |

| RFU10 | / | HUB_SPI_MISO | Module Flash data storage output |

| HUB_UART_RX | / | Smart module RX signal | |

| RFU11 | HUB_H164_CSD | HUB_H164_CSD | 74HC164 data signal |

| RFU12 | / | / | / |

| RFU13 | HUB_H164_CLK | HUB_H164_CLK | 74HC164 clock signal |

| RFU14 | POWER_STA1 | POWER_STA1 | Dual power supply detection signal 1 |

| RFU15 | MS_DATA | MS_DATA | Dual card backup connection signal |

| RFU16 | POWER_STA2 | POWER_STA2 | Dual power supply detection signal 2 |

| RFU17 | MS_ID | MS_ID | Dual card backup identifier signal |

| RFU18 | HUB_CODE4 | HUB_CODE4 | Flash control pin 5 |

Note:

The RFU8 and RFU10 are signal multiplex extension pins. Only one pin from either the Recommended Smart Module Pin or the Recommended Module Flash Pin can be selected at the same time.

Specifications

| Maximum Resolution | 512×384@60Hz (PWM driver ICs)

384×384@60Hz (Common driver ICs) |

|

| Electrical Parameters | Input voltage | DC 3.8 V to 5.5 V |

| Rated current | 0.6 A | |

| Rated power consumption | 3.0 W | |

| Operating Environment | Temperature | -20°C to +70°C |

| Humidity | 10% RH to 90% RH, non-condensing | |

| Storage Environment | Temperature | -25°C to +125°C |

| Humidity | 0% RH to 95% RH, non-condensing | |

| Physical Specifications | Dimensions | 70.0 mm × 45.0 mm × 8.2 mm |

|

Net weight |

18.5 g

Note: It is the weight of a single receiving card only. |

|

| Packing Information | Packing specifications | Each receiving card is packaged in a blister pack. Each packing box contains 80 receiving cards. |

| Packing box dimensions | 392.0 mm × 200.0 mm × 123.0 mm | |

The amount of current and power consumption may vary depending on various factors such as product settings, usage, and environment.