一、What is the main reason for the problem of LED display only showing half of the screen?

How should we repair it?

1. The display area position set is incorrect: This can be adjusted by resetting the display area range size in the display screen playback software

2. Setting font size too large: still adjusting font size while playing software

3. Unit board issue: Of course, the board is broken and cannot be displayed. It is not common to replace the board

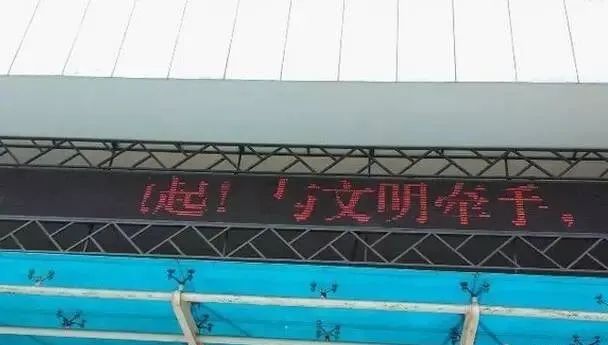

A problem like this is usually a setup problem. It is also possible that the unit has malfunctioned. But the probability is relatively small. Let's take a look at a similar problem as shown in the figure:

This problem is mostly caused by hardware issues, usually caused by the following issues.

1. Power cord issue: As the first excluded object. It is highly likely that the power cord on the unit board is loose, resulting in incomplete display.

2. Power supply issue: This is usually caused by a power module malfunction, and the power supply needs to be replaced, but this situation is not common. As the second target for investigation.

3. Control card damage: Control card damage causes data transmission errors or incomplete transmission.

4. Unit board issue: Of course, the board is broken and cannot be displayed. It is not common to replace the board.

二、 How to handle color deviation on LED display screens?

When looking at the side of the LED display module, the color deviation and decor between the modules are inconsistent. What is the problem?

Firstly, understand the main reasons for the color deviation of LED display modules:

1. Problems with LED lights: (including inconsistent chip parameters, defects in packaging adhesive material, positioning errors during crystal fixation, and errors during color separation), which can affect the emission wavelength, brightness, and angle of LED lights in the same batch. So, there is a very important process in producing LED electronic displays: mixing lights. Mix all LED lights of the same color evenly before inserting them onto the PCB. The advantage of doing so is that it can avoid local color deviation of the LED module.

2. Production process: After the LED module has undergone wave soldering and the LED position has been fixed, it should not be moved again. But many companies often collide and bend LED lights during testing, repair, welding, aging, and transfer processes due to the lack of protection conditions. Then, before applying the glue, a so-called whole line is carried out, which can easily cause the lights on the LED screen to tilt irregularly, leading to color deviation of the module.

3. Power supply issue: When designing LED display screens, it is difficult to have a clear understanding of the materials to be used (including the selection and amount of power supply), resulting in problems in the power supply system and uneven power supply for LED modules.

4. Control system and control IC: Due to the fact that LED display screen manufacturers do not have the design, development, testing, and production capabilities for LED display screen control systems and control ICs. The produced display screen cannot be guaranteed, the only thing that can be done is to adjust various parameters.

Therefore, when the color deviation problem of the LED display module is caused by the LED lights and production process, the module can only be repaired or replaced. When it is a power supply issue, it is necessary to replace the power light, etc. If it is a problem with the control system and IC, we can only request the manufacturer to repair or solve it.

The above are the common causes and solutions of LED strip screen display faults, starting from simple to complex, and troubleshooting the most common problems one by one.

Post time: Jun-26-2023