In order to achieve the best display effect, high-quality LED display screens generally need to be calibrated for brightness and color, so that the brightness and color consistency of the LED display screen after lighting up can reach the best. So why does a high-quality LED display screen need to be calibrated, and how does it need to be calibrated?

Part. 1

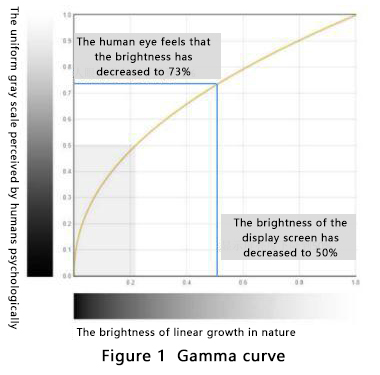

Firstly, it is necessary to understand the basic characteristics of human eye perception of brightness. The actual brightness perceived by the human eye is not linearly related to the brightness emitted by an LED display screen, but rather a non-linear relationship.

For example, when the human eye looks at an LED display screen with an actual brightness of 1000nit, we reduce the brightness to 500nit, resulting in a 50% decrease in actual brightness. However, the perceived brightness of the human eye does not decrease linearly to 50%, but only to 73%.

The non-linear curve between the perceived brightness of the human eye and the actual brightness of the LED display screen is called the gamma curve (as shown in Figure 1). From the gamma curve, it can be seen that the perception of brightness changes by the human eye is relatively subjective, and the actual amplitude of brightness changes on LED displays is not consistent.

Part. 2

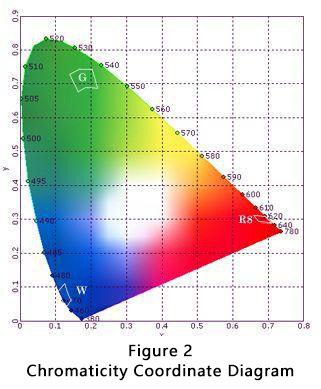

Next, let's learn about the characteristics of color perception changes in the human eye. Figure 2 is a CIE chromaticity chart, where colors can be represented by color coordinates or light wavelength. For example, the wavelength of a common LED display screen is 620 nanometers for a red LED, 525 nanometers for a green LED, and 470 nanometers for a blue LED.

Generally speaking, in a uniform color space, the human eye's tolerance for color difference is Δ Euv=3, also known as visually perceivable color difference. When the color difference between LEDs is less than this value, it is considered that the difference is not significant. When Δ Euv>6, it indicates that the human eye perceives a severe color difference between two colors.

Or it is generally believed that when the wavelength difference is greater than 2-3 nanometers, the human eye can sense the color difference, but the sensitivity of the human eye to different colors still varies, and the wavelength difference that the human eye can perceive for different colors is not fixed.

From the perspective of the variation pattern of brightness and color by the human eye, LED display screens need to control the differences in brightness and color within the range that the human eye cannot perceive, so that the human eye can feel good consistency in brightness and color when watching LED display screens. The brightness and color range of LED packaging devices or LED chips used in LED display screens have a significant impact on the consistency of the display.

Part. 3

When making LED display screens, LED packaging devices with brightness and wavelength within a certain range can be selected. For example, LED devices with brightness span within 10% -20% and wavelength range within 3 nanometers can be selected for production.

Choosing LED devices with a narrow range of brightness and wavelength can basically ensure the consistency of the display screen and achieve good results.

However, the brightness range and wavelength range of the LED packaging devices commonly used in LED display screens may be larger than the ideal range mentioned above, which may result in differences in brightness and color of LED light-emitting chips being visible to the human eye.

Another scenario is COB packaging, although the incoming brightness and wavelength of LED light-emitting chips can be controlled within the ideal range, it can also lead to inconsistent brightness and color.

To solve this inconsistency in LED display screens and improve display quality, point by point correction technology can be used.

Point by point correction

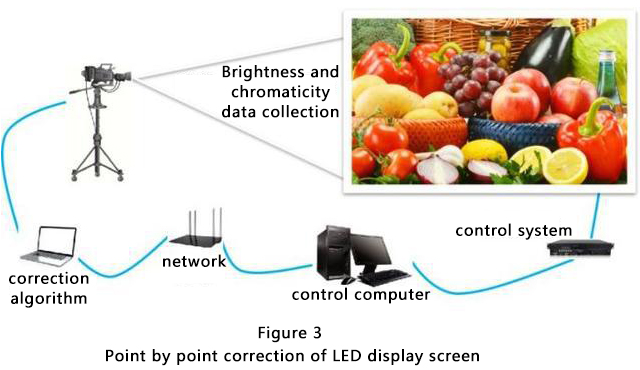

Point by point correction is the process of collecting brightness and chromaticity data for each sub pixel on an LED display screen, providing correction coefficients for each base color sub pixel, and feeding them back to the control system of the display screen. The control system applies the correction coefficients to drive the differences of each base color sub pixel, thereby improving the uniformity of brightness and chromaticity and color fidelity of the display screen.

Summary

The perception of the brightness changes of LED chips by the human eye shows a non-linear relationship with the actual brightness changes of LED chips. This curve is called the gamma curve. The sensitivity of the human eye to different wavelengths of color is different, and LED display screens have better display effects. The brightness and color differences of the display screen should be controlled within a range that the human eye cannot recognize, so that LED display screens can show good consistency.

The brightness and wavelength of LED packaged devices or COB packaged LED light-emitting chips have a certain range. In order to ensure good consistency of LED display screens, point by point correction technology can be used to achieve consistent brightness and chromaticity of high-quality LED display screens and improve display quality.

Post time: Mar-11-2024