01. Basic structural differences

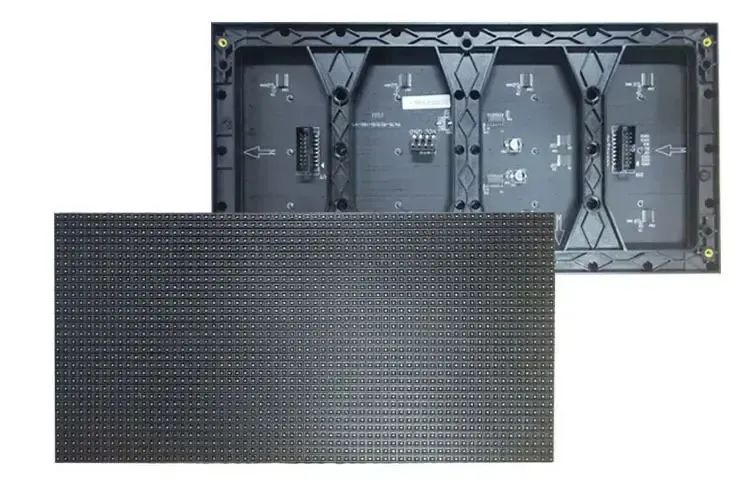

Module

LED module is the core component of LED display screen, which is composed of several LED beads. The size, resolution, brightness and other parameters of LED modules can be customized according to needs. LED modules have the characteristics of high brightness, high definition, and high contrast, which can present very clear and vivid images and videos.

Cabinet

LED cabinet refers to the outer shell of an LED display screen, which is a framework that assembles the various parts of the LED display screen together. It is made of materials such as aluminum alloy and steel, and has good heat dissipation performance, which can ensure the stable operation of LED display screens. The size, weight, thickness and other parameters of the LED cabinet can be customized according to different application scenarios and needs. LED cabinet usually have functions such as waterproof, dustproof, and anti-corrosion, and can operate normally in various harsh environments.

02. Practical application

Screen area size

For LED display screens with indoor point spacing greater than P2.0, regardless of the size of the screen area, it is generally recommended to directly use module splicing for higher cost-effectiveness.

If the small spacing screen is larger than 20 square meters, it is recommended to use a box structure for splicing, and for small spacing screens with smaller areas, it is recommended to use module splicing.

Different installation methods

For floor mounted LED display screens, it is recommended to use box splicing when the back is not enclosed. This is more aesthetically pleasing, practical, and visually appealing, making front and rear maintenance more convenient and efficient.

The LED display screen with module splicing needs to be individually sealed at the back, which may have poor safety, stability, and aesthetics. Generally, it is maintained before, and if it is maintained after, a separate maintenance channel needs to be left.

Evenness

Due to the small size of the module, it is more commonly used in a single display screen, and it is manually spliced, resulting in some defects in the stitching and flatness, which directly affects the appearance, especially in large display screens.

Due to the larger size of the box, fewer pieces are used in a single display screen, so when splicing, it is better to ensure its overall flatness, resulting in a better display effect.

Stability

Modules are generally magnetically installed, with magnets installed at the four corners of each module. Large display screens may experience slight deformation due to thermal expansion and contraction during long-term use, and originally flat displays may experience misalignment issues.

The installation of the box usually requires 10 screws to fix it, which is very stable and not easily affected by external factors.

Price

Compared to modules, for the same model and area, the price of using a box will be slightly higher. This is also because the box is highly integrated, and the box itself is made of die cast aluminum material, so the cost investment will be slightly higher.

Of course, when designing the actual case, we need to choose whether to use a box or a module based on the actual application scenario and requirements. In addition, external factors such as frequent disassembly and budget should be considered to achieve the best effect and experience.

Post time: Apr-01-2024