How to repair these common minor faults?

Firstly, prepare maintenance tools. The five essential items for LED display screen maintenance workers are tweezers, a hot air gun, a soldering iron, a multimeter, and a test card. Other auxiliary materials include solder paste (wire), soldering flux, copper wire, glue, etc.

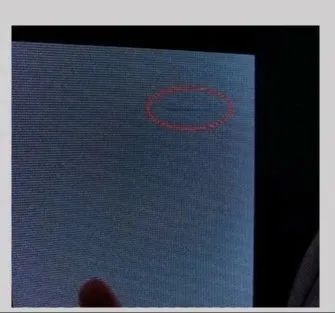

1、The issue of caterpillars

"Caterpillar" is just a metaphorical term, referring to the phenomenon of a long dark and bright strip appearing on some LED display screens under powered conditions without an input source, mostly in red. The root cause of this phenomenon is the leakage of the internal chip of the lamp, or the short circuit of the IC surface circuit behind it, with the former being the majority. In general, when this situation occurs, we only need to hold a hot air gun and blow hot air along the discolored "caterpillar" that is leaking electricity. When we blow it to the problematic light, it is generally OK because the internal leakage chip connection is broken due to heating, but there is still a hidden danger. We only need to find the leaking LED bead and replace it according to the method mentioned above. If there is a short circuit in the circuit of the back IC surface, it is necessary to use a multimeter to measure the relevant IC pin circuit and replace it with a new IC.

2、Local "dead light" problem

Local "dead light" refers to one or several lights on the LED display screen that do not light up. This type of non light up is distinguished as full-time non light up and partial color non light up. Generally, this situation is due to the problem with the light itself, either being damp or the RGB chip being damaged. Our repair method is simple, which is to replace it with the factory provided LED bead spare parts. The tools used are tweezers and hot air guns. After replacing the spare LED beads, Retest with a test card, and if there are no issues, it is already fixed.

3、Local color block missing issue

Friends who are familiar with LED display screens have definitely seen this kind of problem, which is that when the LED display screen is playing normally, there is a small square shaped color block. This problem is usually caused by the burning of the color IC behind the control block. The solution is to replace it with a new IC.

4、Local garbled code problem

The problem of local garbled characters is quite complex, referring to the phenomenon of random flickering of color blocks in certain areas of LED display screens during playback. When this problem occurs, we usually first investigate the connection problem of the signal cable. We can check whether the ribbon cable is burnt out, whether the network cable is loose, and so on. In maintenance practice, we found that the aluminum magnesium wire material is prone to burning out, while the pure copper wire has a longer lifespan. If the entire signal connection is checked and there are no problems, then swapping the faulty LED module with the adjacent normal playing module can basically determine whether it is possible that the LED module corresponding to the abnormal playing area is damaged. The cause of the damage is mostly IC problems, and maintenance and handling can be quite complex. We will not elaborate on the situation here.

5、Partial black screen or large area black screen problem

There are usually several different factors that can lead to this phenomenon. We need to investigate and solve the problem through reasonable methods and steps. Usually, there are four points that can cause black screens on the same LED display screen, which can be investigated one by one:

1、 Loose circuit

(1) Firstly, check and confirm whether the serial cable used to connect the controller is loose, abnormal, or detached. If it turns black at the beginning of the loading process, it is likely due to a loose communication line interrupting the communication process, causing the screen to turn black. Do not mistakenly think that the screen body has not moved, and the line cannot be loose. Please check it yourself first, which is important for quickly solving the problem

(2) Check and confirm whether the HUB distribution board connected to the LED screen and the main control card is tightly connected and inserted upside down

2、 Power supply issue

Please ensure that all hardware, including the control system, is properly powered on. Is the power light flashing or is there a malfunction in the power supply? It is worth noting that using a low-quality power supply is usually prone to this phenomenon

3、 Connection issue with LED unit board

(1) Several consecutive boards do not light up in the vertical direction. Check if the power supply for this column is normal

(2) Several consecutive boards do not light up in the horizontal direction. Check if the cable connection between the normal unit board and the abnormal unit board is connected; Or is the chip 245 functioning properly

4、 Software settings or lamp tube issues

If there is a clear boundary between the two, the possibility of software or settings causing it is high; If there is a uniform transition between the two, it may be a problem with the lamp tube.

Post time: May-06-2024